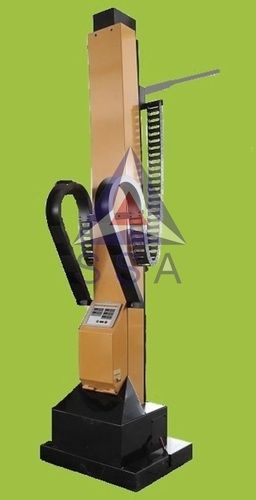

Auto Powder Coating Reciprocator

Price 125000 INR/ Unit

Auto Powder Coating Reciprocator Specification

- Usage

- Industrial

- Material

- Mild Steel / Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Technology

- Powder Coating Automation

- Product Type

- Auto Powder Coating Reciprocator

- Dimension (L*W*H)

- Approx. 1600mm x 400mm x 300mm

- Power Mode

- Electric

- Voltage

- 220V / 380V

- Power Consumption

- Approx. 0.5 - 1 kW

- Engine Configuration

- Servo Motor Driven

- Application

- Industrial Surface Coating

- Weight

- Approx. 60 - 80 kg

- Coating Type

- Powder Coating

- Control System

- Digital PLC Based

- Noise Level

- Low < 70 dB

- Mobility

- Floor Standing, Movable Base

- Reciprocating Speed Control

- Variable Frequency Drive (VFD)

- No. of Guns Supported

- 1 to 4 Guns

- Color

- Customizable

- Display

- LCD Touch Screen

- Stroke Length

- Variable, up to 2500mm

- Operation Mode

- Automatic / Manual

About Auto Powder Coating Reciprocator

Efficient Surface Coating for Industrial Use

The Auto Powder Coating Reciprocator is designed for both general and specific industrial applications, ensuring optimal surface coating on various materials. Featuring variable stroke length, adjustable speed control, and options for automatic or manual use, it enhances coating uniformity and throughput. With mild steel or stainless steel construction, the system supports up to four powder guns and minimizes operational noise. Its matchless automation technology streamlines coating processes for manufacturers and service providers alike.

Export Market Reach and Transaction Process

Our Auto Powder Coating Reciprocator is a preferred choice in main export markets, supported by recognized certifications. Upon proposal amount approval, quotation details are furnished. Packing & Dispatch are handled with careful planning, ensuring product integrity. We accommodate multiple payment terms for customer convenience. With a strong presence as exporter, manufacturer, supplier, and service provider, our quality and efficiency command attention internationally, making each transaction smooth and secure.

FAQ's of Auto Powder Coating Reciprocator:

Q: How does the Auto Powder Coating Reciprocator enhance industrial surface coating operations?

A: The reciprocator offers precise stroke length and speed control, supporting 1 to 4 powder guns. Automated and manual modes, low noise levels, and mobility make it ideal for industrial surface coating, boosting efficiency and finish quality.Q: What materials can this reciprocator be made from?

A: You can choose between mild steel or stainless steel construction, allowing the system to be tailored to specific application and durability needs within industrial environments.Q: Where is the Auto Powder Coating Reciprocator mainly exported?

A: This reciprocator is primarily exported to industrial markets that demand advanced powder coating automation, with a strong presence as a supplier and exporter from India to global clients.Q: What is the process for placing an order and receiving a quotation?

A: To place an order, simply inquire with your specifications and quantity. You will receive a detailed proposal amount and quotation. Packing & Dispatch follow after payment terms are agreed upon, ensuring timely delivery.Q: When is variable speed control beneficial during operation?

A: Variable reciprocation speed control, managed by the integrated VFD, is valuable for adapting to different coating requirements, materials, or application rates, optimizing coverage and reducing material waste.Q: What are the primary benefits of using the digital PLC-based control system?

A: The digital PLC allows for accurate system adjustments, enhances automation reliability, offers flexible operation modes, and makes real-time monitoring via LCD touchscreen simple for any technician.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Equipment Category

Powder Sieving Machine

Price 44000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 2 kW

Material : Stainless Steel

Technology : Other, Vibratory Sieve

Coating Type : Powder Coated

Multi Cyclone Dust Collector

Price 35000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : Variable, depends on unit size and application

Material : Mild Steel / Carbon Steel / Stainless Steel (As per requirement)

Technology : Other, Cyclonic Separation

Coating Type : Powder Coated / Painted (As per requirement)

Bag Filter

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 25 kW

Material : Mild Steel (MS)

Technology : Other, Pulse Jet Cleaning

Coating Type : Powder Coated

Monocylone Powder Coating Booths

Price 107000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 510 kW Kilowatt (kW)

Material : Mild Steel

Technology : Other, Monocyclone Separation

Coating Type : Electrostatic Powder Coating

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free