Coating Booth

Price 125000 INR/ Unit

Coating Booth Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Product Type

- Coating Booth

- Technology

- Spray Coating

- Dimension (L*W*H)

- 3500 x 2000 x 2200 mm

- Power Mode

- Electric

- Voltage

- 380V

- Power Consumption

- 5 kW

- Engine Configuration

- Direct Drive Blower

- Application

- Industrial Coating

- Weight

- 650 kg

- Coating Type

- Powder Coating

- Surface Treatment

- Polished and anti-corrosive coated

- Control Panel

- Digital with timer and safety lock

- Color

- Blue & White

- Noise Level

- 78 dB

- Air Flow

- Multi-stage filtration

- Exhaust System

- High-efficiency exhaust fan

- WorkingSpeed

- Adjustable

- Lighting

- Integrated LED

About Coating Booth

Product details

| Booth Size (mm X mm X mm) | 2m / 3m / 4m ....... |

| Air-Flow Direction | Fully Undershot Type,Cross-Flow Type |

| Heating Mode | Diesel,Electric |

| Material to be painted | Iron,Steel,Aluminum |

Precision and Safety in Spray Coating

Experience reliable industrial coating backed by advanced filtration and exhaust systems. The integrated LED lighting ensures optimal visibility while the digital control panel enhances operational safety and precision through timer and safety lock features. This booth is engineered for high throughput and consistent finishes.

Durable and Efficient Construction

The booth's stainless steel body is polished and coated to resist corrosion, extending product life and minimizing maintenance. Adjustable working speed and automatic processing allow customization for diverse industrial applications, making this coating booth a versatile solution for manufacturers and service providers.

FAQ's of Coating Booth:

Q: How is air quality maintained inside the coating booth?

A: Air quality is upheld through multi-stage filtration, which captures particulate matter and fumes, alongside a high-efficiency exhaust fan. These features ensure a clean and safe environment for operators and consistent coating results.Q: What type of surfaces can be treated in this coating booth?

A: The booth is designed to handle powder coating on various industrial-scale components, particularly those made from metals or materials suitable for spray coating processes.Q: When should the exhaust filters be replaced for optimal performance?

A: Filter replacement frequency depends on usage intensity, but it is recommended to inspect and replace filters periodically, such as monthly or after every major project, to maintain high air purity and machine efficiency.Q: Where can this coating booth be installed?

A: This booth is suitable for installation in industrial manufacturing plants, service workshops, and production facilities that require automated spray coating operations. Its dimensions and weight should be considered during site preparation.Q: What is the process for operating the booth's control panel?

A: The digital control panel features straightforward controls including a timer and safety lock. Operators can set processing duration, adjust speed, and enable safety measures to facilitate smooth, automated coating operations.Q: How does adjustable working speed benefit users?

A: Adjustable speed allows users to fine-tune the coating process depending on the material and application, optimizing coverage and ensuring consistent quality across different jobs.Q: What are the advantages of the booth's surface treatment and construction material?

A: Stainless steel construction with polished and anti-corrosive coating ensures the booth's resilience to harsh chemicals and wear, reducing maintenance and enhancing its operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Mono Cyclone Powder Booth

Price 107000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Material : Mild Steel

Product Type : Mono Cyclone Powder Booth

Usage : Industrial

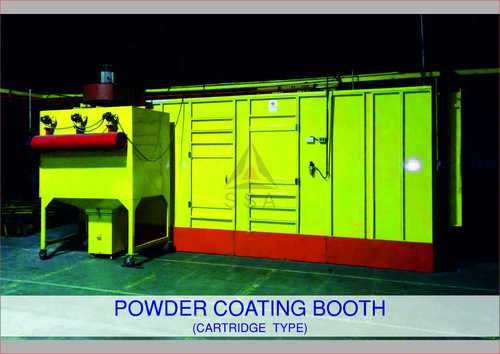

Powder Coating Booth with Cartridge Filter

Price 323000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Material : Stainless Steel

Product Type : Powder Coating Booth with Cartridge Filter

Usage : Industrial

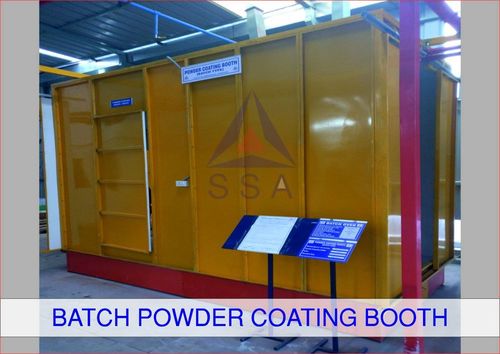

Batch Powder Coating Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 V / 220 V / 415 V Volt (v)

Material : Mild Steel

Product Type : Batch Powder Coating Booth

Usage : Industrial

Cartridge Type Powder Recovery Booth

Price 440000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Material : Stainless Steel

Product Type : Cartridge Type Powder Recovery Booth

Usage : Industrial

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free