Conveyorised Curing Oven

Price 1250000 INR/ Unit

Conveyorised Curing Oven Specification

- Production Capacity

- 300500 kg/hr

- Driven Type

- Electric

- Accessories

- Digital Temperature Controller, Conveyor Belt, Exhaust Fan

- Frequency

- 50 Hz

- Installation Guideline

- Installation by technician; requires 3-phase power supply and exhaust ventilation

- Temperature Range

- Ambient to 250C

- Motor Power

- 2 HP

- Usage & Applications

- Used for powder coating, paint curing, drying and pre-heating applications

- Source

- CATALOG

- Speed

- Adjustable (0.55 m/min)

- Automation Grade

- Semi-Automatic

- Model No

- CCO-6012

- Efficiency (%)

- Up to 98%

- Plastic Processed

- Not applicable (primarily for coatings and curing applications)

- Type

- Conveyorised Curing Oven

- Material

- Mild Steel (MS) body with insulated panels

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Microprocessor Based Temperature Controller

- Drive Type

- Chain Driven Conveyor System

- Voltage

- 415V AC, 3 Phase

- Power

- 9-15 kW (depending on size and model)

- Weight (kg)

- Approx. 1200-1500 kg

- Dimension (L*W*H)

- 6000 x 1200 x 1800 mm (customizable)

- Color

- Industrial Blue & Grey

- Capacity

- Up to 500 kg/hr

- Features

- Even heat distribution, adjustable belt speed, PID temperature controller, efficient thermal insulation

- Power Consumption

- Approx. 1015 Units/hr

- Surface Finish

- Powder Coated

- Machine Type

- Industrial Conveyor Oven

- Insulation Thickness

- 100 mm Ceramic Wool

- Door Type

- Double Insulated Doors

- Belt Material

- Stainless Steel Mesh

- Heat Source

- Electric Heater

- Air Circulation

- Forced Hot Air Recirculation

- Operating Noise Level

- Below 75 dB

- Humidity Control

- Optional (available on request)

- Chamber Length

- 4500 mm (customizable)

- Number of Zones

- Single/Multiple Zones as per requirement

- Conveyor Width

- 900 mm

- Safety Features

- Over-temperature Protection, Emergency Stop

About Conveyorised Curing Oven

Versatile Usage & Application Insights

The Conveyorised Curing Oven is engineered for diverse industrial purposes, including powder coating, paint curing, drying, and pre-heating. Simply load your workpieces onto the adjustable-speed stainless steel mesh belt, set your desired temperature, and let the automated chain-driven conveyor advance items through the single or multiple heating zones. Ideal for both general finishing and specific specialist coatings, this oven streamlines thermal processing with efficiency and reliability.

Domestic Market, Payment & Approvals

Widely recognized across India's industrial sector, the CCO-6012 is the dominant choice for manufacturers and service providers seeking reliable curing equipment. The asking price and delivery charges are determined based on customization and order specifics, with flexible payment terms including advance and delivery-based payments. Certified for safety and efficiency, the oven meets industry compliance standards to ensure high-quality performance and trustworthy results throughout your operations.

FAQ's of Conveyorised Curing Oven:

Q: How does the Conveyorised Curing Oven benefit high-volume curing operations?

A: The oven's chain-driven conveyor and adjustable speed options (0.5-5 m/min) enable continuous processing, supporting production capacities up to 500 kg/hr, which is ideal for demanding industrial workflows.Q: What safety features are integrated into this curing oven?

A: Key safety features include over-temperature protection, an emergency stop system, and double insulated doors, ensuring worker safety and equipment reliability during operation.Q: When should the humidity control option be considered?

A: Humidity control is recommended for applications needing precise atmospheric conditions, such as sensitive coating processes or specialty drying tasks, and can be added upon request.Q: Where is installation support available for this oven model?

A: Installation is handled by certified technicians across India. The process requires a 3-phase power supply and proper exhaust ventilation for optimal performance.Q: What is the process for ordering and delivery?

A: Customers can place orders specifying customization requirements, and delivery is scheduled upon confirmation of payment. Delivery charges and timelines vary as per location and order specification.Q: Which usage applications is this oven best suited for?

A: The oven excels in powder coating, paint curing, drying, and pre-heating, offering reliable results for general fabrication and specialist finishing processes in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Oven Category

Imported Drying Oven

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Off White / Blue

Type : Imported Drying Oven

Drive Type : Electric

Material : Stainless Steel (Inner Chamber), Mild Steel (Outer Body)

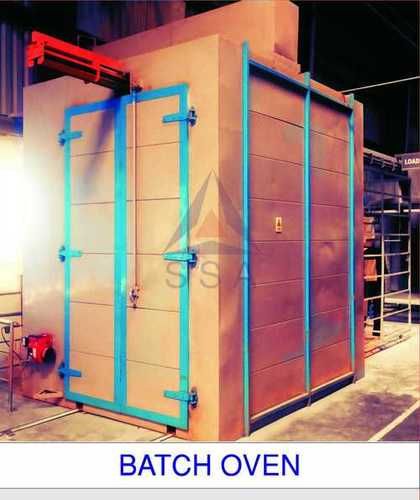

Batch Oven

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Color : Metallic with blue accents

Type : Batch Oven

Drive Type : Electric

Material : Highgrade metal insulated panels

Electric Ground Conveyorised oven

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue (Primary)

Type : Ground Conveyorised Oven

Drive Type : Other, Electrical

Material : Mild steel / stainless steel

Ground Curing Oven

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Type : Ground Curing Oven

Drive Type : Electric

Material : Mild Steel

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free