Dry Ovens

Price 100000 INR/ Unit

Dry Ovens Specification

- Type

- Dry Ovens

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220-440 Volt (v)

- Color

- Multicolor

- Warranty

- 1 Year

- Features

- High accuracy

- Surface Finish

- Polished

Dry Ovens Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Delivery Time

- 3-4 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Dry Ovens

We are leading manufacturer of Camel Back Oven.

Our organization has gained recognition as the affluent manufacturer and trader of a qualitative array of Camel Back Oven. Offered industrial ovens are designed using optimum grade raw material and contemporary machinery. We guarantee our clients that these industrial ovens are quality tested on well-defined parameters to meet up worldwide standards. Besides, our prestigious clients can purchase these ovens at highly competitive price.

Specifications:

Our design of the Camel Back Curing Oven provides an efficacious and an ideal curing solution for a conveyorised plant

Our design provides maximum thermal efficiency and accounts minimum heat losses associated with the oven openings. Also their space utilization on the shop floor is minimal

FEATURES

- Low Maintenance

- Multi Point Temperature Monitoring

- Ambient Temperature Of Outer Wall

- Multi Fuel Running Option

- ÃHighly Fuel Efficient

- Doubled Walled Construction

- Uniform Heating Ducting Design

- Insulated Door Openings

- TTR Approved Designs

- Safe limits of Insulations

- Multi point temp monitoring

- Audio & Visual Alarm Panels

- Optimum Fuel Utilization By Auto Cut-OffFiring Convenient Usage by Control Panel

TECHNICAL SPECIFICATIONS:

| Blower Type | Backward curved dynamically balanced |

| Blower Capacity (CMH) | 2500 / 3500 / 5500 / 7500 / 9500 |

| Motor Capacity (HP) | 1 / 2 / 3 / 5 / 7.5 |

| Maximum Designed Temp (°C) | 80 / 150 / 200 / 250 |

| Curing/Drying Temp (°C) | 70 / 140 / 180 / 210 |

| Heating Source (Hot Air Generator (HAG)) | Electric / Gas (LPG/PNG) / LDO (Diesel) |

| Thermal Rating (Lacs Kcal/hr) | 0.5 / 0.8 / 1 / 1.5 / 2 /2.5 /3 |

| Material of Const. (mm) - HAG | SS 316 , SS 304 , SS 202 |

| Insulation Thickness (mm) | 50 / 100 / 125 / 150 / 200 |

| Insulation Type | Glasswool / Rock wool |

| Finishing (Inside) | High Temp. Silver Paint |

| Finishing (Outside) | Bright Silver Paint |

| Control Panel c/w Wiring | Included |

Versatile Heating Solutions

These drying ovens accommodate multiple heating methods-including gas, diesel, and electrical-making them adaptable to diverse industrial needs. The Camel Back Type design ensures even heat distribution and efficient operation, suitable for high-demand environments.

Reliable Manufacturing and Export Services

Manufactured and exported by reputable providers in India, these ovens come with comprehensive after-sales support. Whether you require installation guidance, maintenance, or operational training, professional assistance is readily available to ensure seamless performance.

FAQ's of Dry Ovens:

Q: How do Camel Back Type Drying Ovens operate with different heating methods?

A: Camel Back Type Drying Ovens are designed to function efficiently using gas, diesel, or electrical heating systems. Gas is the standard power source, providing rapid and controlled thermal output for consistent drying and curing. Switching between heating methods may be possible based on specific operational needs.Q: What are the benefits of using a painted surface finish on these drying ovens?

A: A painted surface finish not only enhances the appearance of the oven but also offers protection against corrosion, wear, and chemical exposure. This extends the oven's longevity, eases cleaning, and maintains its performance in demanding industrial environments.Q: When is it ideal to use a Camel Back Type Drying Oven?

A: Camel Back Type Drying Ovens are best suited for applications requiring uniform heat distribution, such as drying, curing, or baking components in automotive, pharmaceutical, and manufacturing industries. They are ideal when reliability, efficiency, and scalability are essential.Q: Where can these drying ovens be installed and used?

A: These ovens are versatile and can be installed in industrial facilities, factories, and manufacturing plants across India and internationally. Installation assistance and service support are provided by the manufacturer and exporter to ensure proper setup anywhere required.Q: What is the process for purchasing and installing a new Camel Back Type Drying Oven from India?

A: To purchase a new Camel Back Type Drying Oven, contact the manufacturer, exporter, or supplier directly. They will guide you through selecting specifications, provide quotations, and arrange shipping. Installation and commissioning support is typically offered to help you get started quickly.Q: How is the drying process controlled and monitored in these ovens?

A: The ovens are equipped with precise temperature controls and monitoring systems that allow operators to set and maintain optimal drying parameters. This ensures accurate, repeatable results while minimizing energy consumption and maximizing safety.Q: What are the main advantages of choosing an Indian exporter or manufacturer for these ovens?

A: Indian exporters and manufacturers are known for providing high-quality, cost-effective drying ovens with comprehensive after-sales service. Their expertise in customization and reliable logistics ensures timely delivery and robust support for global customers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Oven Category

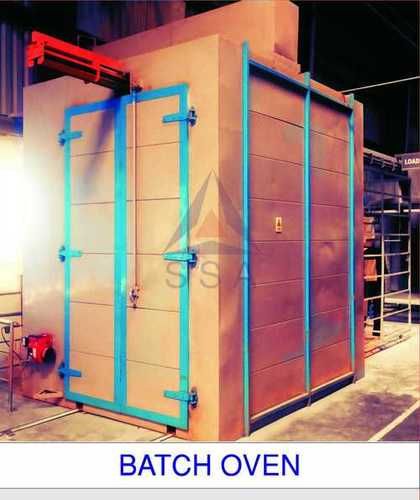

Batch Oven

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Material : Highgrade metal insulated panels

Drive Type : Electric

Color : Metallic with blue accents

Source : CATALOG

Coating Oven

Price 86000 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel and Stainless Steel

Drive Type : Other, Chain Drive

Color : Orange and Silver

Source : CATALOG

Paint Baking Oven

Price 1150000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Drive Type : Electric

Color : Blue and Red

Source : CATALOG

Automatic Drying Oven

Price 260000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal (likely steel)

Drive Type : Electric

Color : Blue and Silver

Source : CATALOG

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS