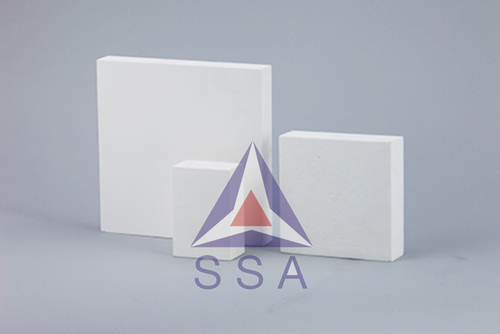

Fluidising Tile

Price 800 INR/ Unit

Fluidising Tile Specification

- Usage

- Industrial

- Surface

- Smooth, porous

- Technology

- Air fluidisation

- Attributes

- Even air distribution, high durability

- Product Type

- Fluidising Tile

- Power Source

- Compressed air

- Color

- White

- Portable

- No

- Protection System

- Moisture and wear resistant

- Material

- Ceramic

- Density

- High

- Shape

- Rectangular/Square

- Installation

- Embedded in vessel base or side walls

- Maintenance

- Low maintenance

- Size

- Standard and custom sizes available

- Permeability

- Optimized for fluidisation efficiency

- Temperature Resistance

- Up to 900°C

- Application

- Powder handling, silos, and hoppers

- Thickness

- 10-25 mm

Fluidising Tile Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Delivery Time

- 1 - 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Fluidising Tile

Product Description:

Our company has gained name and fame for offering Fluidizing Tile to clients. Offered range is made by our vendors using modern machines and top grade quality material as per set industrial norms. This product is acclaimed for elegant design, impeccable strength and fine finish and many more attributes.

Fluidising Tiles are used to fluidise powder. It is the process of moving, transporting and treating powders and other granular materials by injection of air to make the powder act as a fluid. This means that air passes through a porous filter material where it is finely distributed and then creates a cushion or film to considerably reduce the friction between material and base. RMCS Fluidising Tiles are of the highest quality.

Features:

- Perforated fluidising tile for powder coating machine hopper available in different sizes and shapes

- High: strength

- Precise: design

- Quality: assured

Precision-Engineered for Industrial Fluidisation

Each Fluidising Tile is crafted with high-density ceramic and optimized porosity to deliver consistent air diffusion and reliable performance. Available in rectangular and square shapes, the tiles can be tailored in size and thickness to fit specific industrial requirements, facilitating seamless integration into powder handling systems like silos and hoppers.

Advanced Durability and Protection

With a temperature resistance up to 900C and a special moisture and wear-resistant surface, these tiles maintain integrity in demanding conditions. Their robust construction ensures longevity, while the low-maintenance requirements allow for efficient, uninterrupted operation.

FAQ's of Fluidising Tile:

Q: How is a Fluidising Tile installed in industrial setups?

A: Fluidising Tiles are embedded into the base or side walls of vessels such as silos and hoppers. Installation is straightforward and can be tailored to accommodate both standard and custom sizes, ensuring compatibility with a wide variety of industrial setups.Q: What makes these Fluidising Tiles suitable for high-temperature powder handling?

A: Constructed from high-density ceramic, the tiles can withstand continuous exposure to temperatures up to 900C, making them ideal for handling powders under extreme industrial conditions.Q: When should Fluidising Tiles be used in powder handling processes?

A: Fluidising Tiles are best used whenever a smooth, uninterrupted flow of powders is essential, especially in systems prone to material bridging or rat-holing, such as silos, hoppers, and other bulk storage vessels.Q: Where can these Fluidising Tiles be effectively utilized?

A: These tiles are perfect for use in a variety of industrial settings, particularly where consistent material flow is critical-such as in powder processing plants, bulk storage silos, and automated hopper systems.Q: What process ensures even air distribution in these tiles?

A: The advanced air fluidisation technology and optimized permeability of the porous ceramic structure allow for uniform air passage, eliminating dead zones and ensuring even powder movement throughout the vessel.Q: How does the use of Fluidising Tiles benefit industrial applications?

A: By offering even air distribution, high durability, and low maintenance needs, these tiles significantly enhance material flow, reduce downtime, and improve overall operational efficiency in powder handling applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paint Shop Accessories Category

Anode Cells

Price 2500 INR / Unit

Minimum Order Quantity : 10 Units

Type : Other, Electrolytic Anode Cell

Portable : No

Surface : Other , Polished

Power Source : Electric

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free