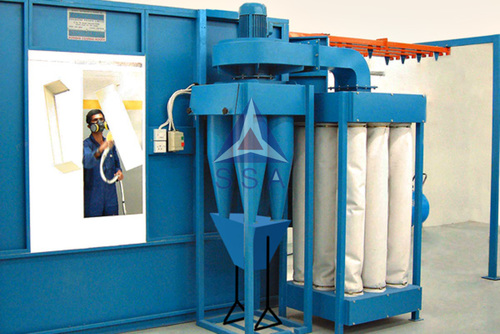

Multi Cyclone Powder Booth

Price 206000 INR/ Unit

Multi Cyclone Powder Booth Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Powder Coating

- Condition

- New

- Product Type

- Multi Cyclone Powder Booth

- Technology

- Multi Cyclone Separation

- Dimension (L*W*H)

- Customized as per requirement

- Power Mode

- Electric

- Voltage

- 415 V

- Power Consumption

- 3-5 kW (Depending on size and configuration)

- Application

- Industrial Powder Coating

- Weight

- Up to 2000 kg (Depends on System Size)

- Coating Type

- Powder Coating

- Air Flow Capacity

- 7000 - 25000 m³/h (Model Dependent)

- Booth Type

- Down Draft

- Noise Level

- <78 dB

- Filtration Efficiency

- Over 98%

- Extraction Fans

- Centrifugal Type

- No. of Cyclones

- 6-12 (Depends on Model)

- Door Type

- Manual / Pneumatic Sliding

- Recovery System

- Multi Cyclone with Secondary Filter

- Installation

- On Site by Manufacturer

- Control Panel

- PLC Based / Manual

- Surface Finish

- Painted / Powder Coated

- Lighting

- LED or Fluorescent Fittings

About Multi Cyclone Powder Booth

Product details

| Booth Size (mm X mm X mm) | 2000 / 2500 / 3000 / mm............. |

| Air-Flow Direction | Lateral Undershot Type,Cross-Flow Type,Fully Undershot Type |

| Heating Mode | Diesel,Electric, Gas |

| Material to be painted | Steel,Aluminum,Iron |

Advanced Filtration Technology

The powder booth employs multi-cyclone separation, capturing over 98% of powder particles. Circulation airflow rates range from 7000 to 25000 m3/h depending on model size, while secondary filtration protects the work environment. This technology guarantees precise powder recovery, minimizing waste and maximizing coating efficiency.

Robust User-Friendly Design

Manufactured from high-grade mild steel with various surface finishes, the booth is engineered for durability and easy maintenance. The down draft configuration and centrifugal fans provide consistent extraction, ensuring operator safety. Flexible control via PLC or manual operation and tailored doors boost accessibility and adaptability.

FAQ's of Multi Cyclone Powder Booth:

Q: How does the Multi Cyclone Powder Booth achieve over 98% filtration efficiency?

A: This booth uses a multi-cyclone separation mechanism combined with a secondary filter, efficiently isolating powder particles during the coating process and recovering them for re-use or disposal. The advanced airflow management ensures exhaustive particulate removal, exceeding 98% filtration.Q: What industries benefit most from installing this powder booth?

A: Industries engaged in high-volume or continuous powder coating-such as automotive, metal fabrication, and furniture manufacturing-benefit significantly due to the booth's efficient recovery system, customizable capacities, and robust safety features.Q: Where is the Multi Cyclone Powder Booth typically installed?

A: The powder booth is designed for on-site installation at industrial premises by the manufacturer, ensuring it fits precise space and operation requirements. Its dimensions are customized for each client's facility layout and production scale.Q: What is the process for powder recovery in this booth?

A: Powder is extracted via a robust down draft system and passes through multiple cyclones, which remove most particulates. Residual powder is captured in the secondary filter before clean air is expelled, optimizing recovery and workplace cleanliness.Q: When should businesses consider upgrading to a Multi Cyclone Powder Booth?

A: Businesses experiencing excessive powder waste, poor air quality, or inconsistent coating results should consider this booth. Its modern recovery system, high efficiency, and automated controls provide substantial operational improvements over older technologies.Q: How do the booth's control panel and door options enhance operation?

A: Users can choose between PLC-based automatic control and manual switching for precise process adjustments. Door options include manual and pneumatic sliding types, ensuring convenient access and compatibility with various plant layouts.Q: What are the key benefits of using a Multi Cyclone Powder Booth for powder coating?

A: Key benefits include high filtration efficiency, reduced powder wastage, improved workplace safety, noise levels below 78 dB, and flexible configuration to meet specific industrial demands. The booth supports optimal product quality and cost-effective operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Plastic Powder Coating Booth

Price 611000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Product Type : Plastic Powder Coating Booth

Usage : Industrial

SS Powder Booth

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Stainless Steel

Product Type : SS Powder Booth

Usage : Industrial

Powder Booth

Price 260000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Product Type : Powder Booth

Usage : Industrial

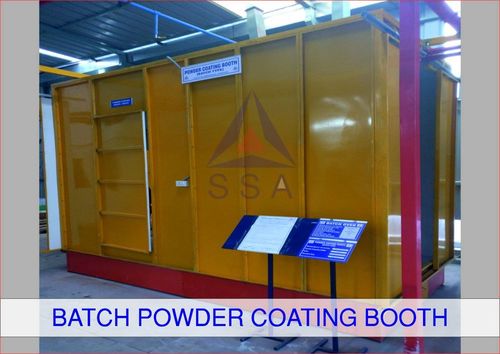

Batch Powder Coating Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Product Type : Batch Powder Coating Booth

Usage : Industrial

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS