TTR or Oven Profiling Temperature Recorders

Price 10000 INR/ Unit

TTR or Oven Profiling Temperature Recorders Specification

- Usage

- Industrial

- Material

- Aluminum & Stainless Steel body

- Processing Type

- Electronic

- Condition

- New

- Technology

- Digital Data Logging

- Product Type

- Temperature Recorders

- Dimension (L*W*H)

- 182 mm x 102 mm x 42 mm

- Power Mode

- Battery Operated

- Voltage

- 3.6V rechargeable

- Power Consumption

- Low, suitable for prolonged profiling

- Application

- Oven Profiling, Temperature Recording, Industrial Process Monitoring

- Weight

- Approx. 850 g

- Coating Type

- Anodized & Powder coated

- Data Storage Capacity

- 100,000 readings

- Battery Life

- Up to 100 hours continuous

- Protection

- Thermal Barrier Housing

- Sampling Interval

- Programmable from 0.1s to 60min

- Operating Environment

- -20°C to +70°C

- Communication Interface

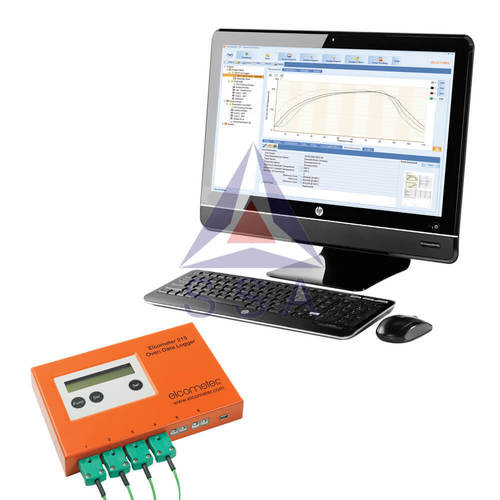

- USB & Software compatible

- Calibration

- Factory Calibrated, User Recalibration supported

- Temperature Range

- -200°C to +1200°C

- Number of Channels

- Up to 6 channels

- Sensor Type

- High-Precision Thermocouple Input

- Working Speed

- Real-time logging

- Display Type

- LCD Digital Display

TTR or Oven Profiling Temperature Recorders Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cheque

- Main Domestic Market

- All India

About TTR or Oven Profiling Temperature Recorders

OVEN PROFILING/ OVEN TEMPERATURE LOGGING

The Curing oven maintaining temperature at around 200 Degrees is the utmost important criteria to complete the coating process.

SSA designed system can log the temperature reading which can be coupled with a feedback alarm system to easy monitoring.

Feature

- To record and revisit the data of oven temperature could be useful for quality checks

- Any aberration on shop floor if unattended can be revisited by the superior management.

- Night Shifts productions can be better accountable.

Product details

Temperature Range | 0 To 220 Degree Celsius |

Frequency | 0.05 Seconds |

Brand | Grant |

Operating Temperature | Upto 220 Degree Celsius |

Material | Ttr |

Accuracy | 2 Degree Celsius |

High-Precision Multi-Channel Monitoring

Monitor multiple temperature points simultaneously with support for up to six thermocouple inputs. Ideal for comprehensive oven profiling, process optimization, or quality control, this recorder ensures accurate data collection from various locations within your process environment.

Robust Construction & Thermal Protection

Encased in a durable aluminum and stainless steel body with anodized and powder-coated finishes, the recorder features a thermal barrier housing to withstand demanding industrial settings. It operates reliably in temperatures from -20C to +70C and through rapid temperature changes, safeguarding internal electronics for long-term use.

Digital Logging and Flexible Data Management

With a large LCD display and up to 100,000 reading storage capacity, this recorder makes data review simple. The USB interface and compatible software allow efficient download, analysis, and archiving of temperature data, streamlining integration into quality systems and process audits.

FAQ's of TTR or Oven Profiling Temperature Recorders:

Q: How can I use the temperature recorder for oven profiling and industrial process monitoring?

A: Simply connect the high-precision thermocouple sensors to key locations within your oven or industrial process. The recorder will log real-time temperature data across up to six channels, helping identify temperature variations and optimize processes for consistent product quality.Q: What are the benefits of the factory calibration and user recalibration features?

A: Factory calibration guarantees initial measurement accuracy, while user recalibration support allows you to maintain precision over the device's lifespan, addressing any drift and ensuring reliable performance during ongoing industrial applications.Q: When should I program the sampling interval, and what range is available?

A: The sampling interval can be customized from 0.1 seconds up to 60 minutes, depending on how frequently you need temperature data. For rapid thermal processes, shorter intervals capture detailed changes; for slower variations, longer intervals conserve storage and battery life.Q: Where can I access and manage recorded temperature data?

A: Data is conveniently reviewed on the LCD display, and for advanced analysis, the recorder connects via USB to compatible software on your PC. This allows for efficient data transfer, graphing, and report generation right from your worksite or laboratory.Q: What protective features increase the durability of this recorder in harsh environments?

A: The recorder's enclosure uses anodized, powder-coated aluminum and stainless steel alongside a thermal barrier housing. This construction protects against physical damage and high temperatures, ensuring reliable performance even in demanding industrial or oven settings.Q: How does the battery life support prolonged and portable monitoring?

A: Operating for up to 100 hours continuously on a single 3.6V rechargeable battery, the recorder is excellent for lengthy profiling tasks. Its low power consumption also means less frequent recharging, enhancing portability and convenience on the shop floor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paint shop services Category

Paint Shop Relocation

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Coating Type : Powder Coated

Material : Mild Steel

Application : Industrial Paint Shop Relocation

Paint Shop Training

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Coating Type : Powder Coating

Material : Other

Application : Industrial Paint Shop Training

Paint Shop Consultancy

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Coating Type : Powder Coating/Liquid Coating

Material : Steel

Application : Industrial Paint Shop

Paint Shop Audit Services

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : Other, New Service

Coating Type : All Industrial Coating Lines

Material : As Per Project Requirement

Application : Paint Shop Process Evaluation & Optimization

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free