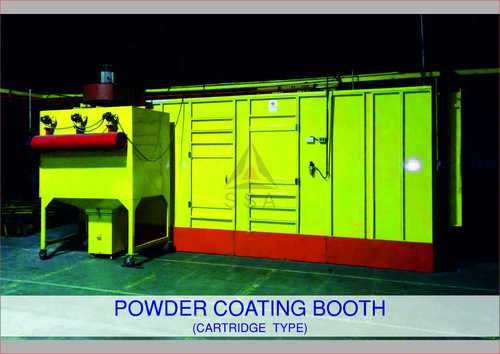

Cartridge Type Powder Recovery Booth

Price 440000 INR/ Unit

Cartridge Type Powder Recovery Booth Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Processing Type

- Powder Recovery

- Condition

- New

- Product Type

- Cartridge Type Powder Recovery Booth

- Technology

- Cartridge Filtration

- Dimension (L*W*H)

- 2000 x 1500 x 2200 mm

- Power Mode

- Electric

- Voltage

- 415 V

- Power Consumption

- 3.7 kW

- Application

- Powder Coating Recovery

- Weight

- Approx. 400 kg

- Coating Type

- Powder Coating

- Filter Type

- High-efficiency Cartridge Filter

- Filtration Efficiency

- Over 99%

- Booth Type

- Modular Booth

- Noise Level

- Below 80 dB

- Number of Cartridge Filters

- 2

- Cleaning Method

- Reverse Pulse Jet

- Working Speed

- Variable

- Lighting

- Integrated LED

- Air Flow Capacity

- 3000-4000 CFM

About Cartridge Type Powder Recovery Booth

Product details

| Air-Flow Direction | Cross-Flow Type, Fully Undershot Type, Lateral Undershot Type |

| Booth Size (mm X mm X mm) | Customised |

| Heating Mode | Diesel, Electric, Infrared Ray, Gas |

| Material to be painted | Steel, Aluminum, Iron |

High-Efficiency Filtration for Enhanced Air Quality

Our cartridge booth uses high-efficiency cartridge filters, capturing over 99% of airborne powder particles. This advanced filtration technology keeps the workspace clean, reduces health risks, and supports compliance with industrial standards. The booth automatically maintains optimal performance with its reverse pulse jet cleaning method, ensuring minimal filter maintenance and long operational life.

Modular Design for Flexible Industrial Use

Designed as a modular system, this powder recovery booth provides versatile installation in various industrial layouts. Its sturdy stainless steel construction offers durability, while its integrated LED lighting and variable working speeds cater to different operational demands. The user-friendly features help streamline powder coating recovery processes and boost productivity in manufacturing or service settings.

FAQ's of Cartridge Type Powder Recovery Booth:

Q: How does the reverse pulse jet cleaning process work in the cartridge type powder recovery booth?

A: The reverse pulse jet cleaning mechanism periodically releases controlled bursts of compressed air through the filters, effectively dislodging accumulated powder from the filter surface. This automated process maintains high filtration efficiency and extends the life of the cartridge filters, reducing downtime and maintenance requirements.Q: What are the key benefits of using a modular cartridge type powder recovery booth for industrial applications?

A: This booth offers over 99% filtration efficiency, ensuring cleaner air and safer working conditions. Its modular design allows for flexible integration into various industrial setups, while features such as integrated LED lighting and variable working speed provide added convenience and energy efficiency in powder recovery operations.Q: Where can this powder recovery booth be installed, and what industries benefit most?

A: The booth is suitable for installation in industrial plants, manufacturing units, and powder coating facilities across sectors such as automotive, furniture, and metal fabrication. Its modular design adapts easily to different workspace configurations, making it ideal for both new setups and existing operations.Q: What maintenance is required to ensure optimal performance of the cartridge filters?

A: The booth's reverse pulse jet cleaning significantly reduces manual maintenance by automatically cleaning the cartridge filters. However, regular visual inspections and periodic checks on the air supply and filters are recommended to ensure reliable performance and maximize filter lifespan.Q: When is the best time to utilize the cartridge type powder recovery booth in the production process?

A: It should be used during and after powder coating applications to recover excess powder and purify air within the work area. Continuous operation during coating processes ensures minimum powder wastage, safety compliance, and efficiency throughout production shifts.Q: How does the booth maintain low noise levels during operation?

A: The booth is designed with noise reduction in mind, maintaining operational sound below 80 dB. Careful integration of airflow systems and insulation ensures minimal disturbance, creating a safer and more comfortable workspace for operators.Q: What advantages does the high-efficiency cartridge filter provide over other filtration technologies?

A: High-efficiency cartridge filters offer superior particle capture, compact design, and easy maintenance compared to traditional bag filters or cyclones. Their quick-cleaning capability ensures consistent efficiency and lower operational costs, making them ideal for industrial powder recovery applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Nano Powder Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Power Mode : Electric

Voltage : 110 V / 220 V / 415 V Volt (v)

Application : Powder Coating Recovery in Industrial Settings

Manual Coating Booth

Price 53000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Power Mode : Electric

Voltage : 220440 Volt (v)

Application : Powder Coating Recovery in Industrial Settings

SS Powder Coating Booth

Price 350000 INR / Piece

Minimum Order Quantity : 1 Plant

Condition : New

Power Mode : Electric

Voltage : 220415 V AC Volt (v)

Application : Industrial metal finishing, metal furniture, automobile parts, etc.

Nano Cartridge Booth

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Power Mode : Electric

Voltage : 220440 Volt (v)

Application : Powder Coating Recovery in Industrial Settings

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free