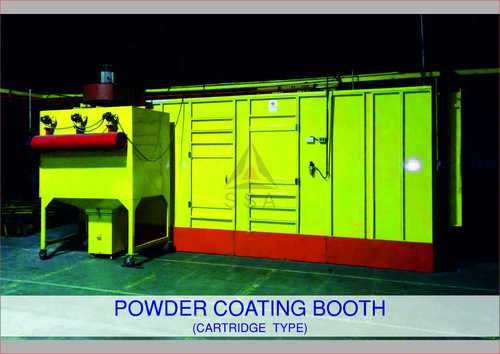

Nano Powder Booth

Price 116000 INR/ Unit

Nano Powder Booth Specification

- Usage

- Industrial

- Material

- MS / AL

- Size

- Standard

- Processing Type

- Standard

- Condition

- New

- Product Type

- Nano Powder Booth

- Color

- Multicolor

- Power Mode

- Electric

- Voltage

- 110 V / 220 V / 415 V Volt (v)

- Engine Configuration

- Triple Cyclone

- Application

- Powder Coating Recovery in Industrial Settings

- Coating Type

- Manual

Nano Powder Booth Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- 20 Units Per Year

- Delivery Time

- 3-4 Years

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Nano Powder Booth

Product Description:

Our range of Nano Cartridge Booth facility includes basic batch booth to conveyorised with auto reciprocators and auto guns. The powder recovery is offered in all denominations from basic mono cyclone to multi cyclones and finally cartridge recovery system. We also offer ductless powder coating booth which are apt for small size components and also useful to contain terminal fines to the atmosphere even if it is 2% or less. We offer multiple colour cartridge systems where there are number of colour changes are envisaged frequently. The booths are offered in SS, CRCA-Powder Coated, and CRCA-Liquid Painted as per agreement. Their basic purpose is to collect the over sprayed powder throws off the powder coating gun. The recovery booths are of various types depending upon their increasing efficiency; they are single cyclone, multi cyclone and cartridge type.

Our range of Nano Powder Booth facility includes basic batch booth to conveyorised with auto reciprocators and auto guns.

Some of the advantages which our unique design which makes us stands apart from our competitors are:

- Provides Maximum Efficiency in its Class

- Durable & Long Life

- Maintenance Free

- Environment Friendly

- Provides Quick Colour

Product details

| Booth Size (mm X mm X mm) | Customized |

| Air-Flow Direction | Cross-Flow Type |

| Heating Mode | Diesel |

| Material to be painted | Aluminum,Iron |

Advanced Protection System for Safe Operation

Our Nano Powder Booth comes with an integrated protection system that safeguards operators from powder exposure. This protective feature enhances workplace safety by effectively containing airborne particles during the coating process. Regular maintenance and adherence to usage guidelines ensure optimal performance of the protection system.

Versatile Design for Batch and Conveyorized Operations

The booth is designed for flexibility, supporting both batch and conveyorized workflows in industrial settings. This versatility allows manufacturers to adapt the system to their specific production requirements, improving productivity and accommodating various project sizes efficiently.

FAQ's of Nano Powder Booth:

Q: How does the Nano Powder Booth with Protection System improve workplace safety?

A: The protection system actively contains powder particles during the coating process, reducing operator exposure and keeping the work environment cleaner and safer.Q: What types of materials can the booth accommodate?

A: The booth is constructed from mild steel (MS) and aluminum (AL), making it suitable for various industrial powder coating applications on compatible surfaces.Q: When is it recommended to use the batch versus conveyorized type?

A: Batch systems are ideal for small to medium runs or customized items, while conveyorized types suit continuous, high-volume operations requiring greater throughput.Q: Where can this powder coating booth be installed?

A: Its portable design makes it suitable for installation in diverse industrial environments across India, whether as a stationary or mobile solution within a facility.Q: What is the process of powder coating in this booth?

A: Powder is manually applied to metal surfaces, then cured. The booth uses suction feed technology to efficiently collect overspray and maintain clean air inside the workspace.Q: How does using this system benefit industrial operations?

A: By ensuring a controlled, efficient coating environment and enhancing operator safety, the system improves product quality and operational efficiency over traditional methods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Plastic Powder Coating Booth

Price 611000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Powder Coating Recovery in Industrial Settings

Voltage : 220440 Volt (v)

Condition : New

Power Mode : Electric

Powder Coating Booth with Mono Cyclone

Price 250000 INR / Piece

Minimum Order Quantity : 1 Plant

Application : Powder Coating Recovery in Industrial Settings

Voltage : 110 V / 220 V / 415 V Volt (v)

Condition : New

Power Mode : Electric

Mono Cyclone Booth

Price 60000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Powder Coating Recovery in Industrial Settings

Voltage : 220440 Volt (v)

Condition : New

Power Mode : Electric

Cartridge Type Powder Recovery Booth

Price 440000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Powder Coating Recovery

Voltage : 415 V

Condition : New

Power Mode : Electric

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free