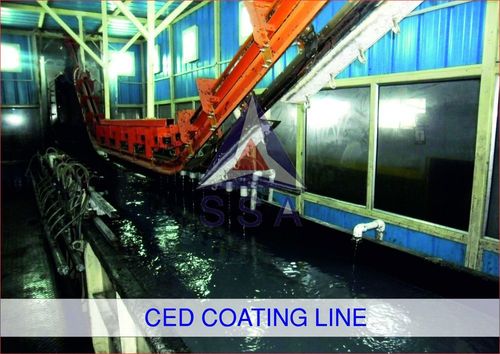

Dunking Type CED Plant

Price 2200000 INR/ Unit

Dunking Type CED Plant Specification

- Tank Capacity

- 1000-10000 Liters (customizable)

- Temperature Range

- 20C - 30C

- Concentration

- As per process requirement

- Grade Standard

- Industrial Grade

- Ph Level

- 5.8 6.2

- Packaging Type

- Standard Export/Industrial Packaging

- Shelf Life

- 12 months (for paint and chemicals)

- Chemical Name

- Cathodic Electro Deposition (CED) Paint

- Usage

- Industrial

- Equipment Type

- Dunking Type CED Plant

- Product Type

- Dunking Type CED Plant

- Dimension (L*W*H)

- Customized as per requirement

- Voltage

- 380-415V, 3 Phase, 50 Hz

- Installation & Commissioning

- Provided by manufacturer

- Application

- Automotive parts, industrial components, fabrication items

- Power Source

- Electric

- After Sales Service

- Available

- Surface Treatment Capacity

- Up to 2000 sq.m/day

- Control Panel

- PLC based / Manual

- Coating Thickness

- 15 30 microns

- Heating System

- Electrical/Steam (as required)

- Material of Construction

- Mild Steel/SS 304/SS 316

- Automation Grade

- Semi-automatic/Automatic (customized)

About Dunking Type CED Plant

Dunking Type CED Plant: Industrial Versatility & Competitive Advantages

Specifically designed for industrial usage, the Dunking Type CED Plant suits automotive parts, industrial components, and fabrication items. With customized tank capacities and flexible automation grades, it adapts to diverse processes, ensuring optimum cathodic electro deposition. Its unrivaled daily surface treatment capacity, phenomenal coating uniformity, and manufacturer-provided installation & after-sales service make it a best-in-class solution, providing users with reliability and efficiency beyond compare.

Export Markets & Domestic Reach: Packing, Dispatch, and Sample Policy

Handed over after rigorous testing, each Dunking Type CED Plant is packed and dispatched using export-grade packaging. The main export markets include Southeast Asia, the Middle East, and Africa, while robust sample policies facilitate easy evaluation for industrial buyers. In India, key domestic markets are covered by an extensive supplier network, ensuring smooth delivery, reliable installation, and ongoing support. Every transaction benefits from standardized packaging and transparent policies.

FAQ's of Dunking Type CED Plant:

Q: How does the Dunking Type CED Plant benefit industrial surface treatment processes?

A: The Dunking Type CED Plant offers unrivaled efficiency and phenomenal coating uniformity, enabling industries to treat up to 2,000 sq.m/day. Its customizability and advanced control systems allow precise application on a range of automotive, industrial, and fabricated components for optimum protection and finish.Q: What applications can the Dunking Type CED Plant be used for?

A: This equipment is ideal for treating automotive parts, industrial components, and fabrication items. Its versatility allows it to handle multiple surface types, ensuring superior corrosion resistance through cathodic electro deposition.Q: Where is the Dunking Type CED Plant primarily exported?

A: It is mainly exported to Southeast Asia, Africa, and the Middle East. Standard export/industrial packaging guarantees safe transit, while sample policies encourage international buyers to evaluate quality before ordering.Q: What is the installation and commissioning process for the Dunking Type CED Plant?

A: The installation and commissioning are handled directly by the manufacturer, ensuring seamless setup and optimal operational performance. This comprehensive service includes technical guidance and training for plant operators.Q: Which control options are available for operating the plant?

A: Users can opt for either a PLC-based automatic system or manual control, catering to various process requirements. This flexibility makes it easy to integrate the plant into new or existing production lines.Q: When should the paint and chemicals be replaced in the CED Plant?

A: The CED paint and chemicals have a shelf life of 12 months. It is recommended to monitor concentration and pH regularly and replace them according to process requirements to maintain coating quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

Automatic CED Plant

Price 15000000 INR / Plant

Minimum Order Quantity : 1 Plant

Shelf Life : 2 Years

Voltage : 220440 Volt (v)

Tank Capacity : 1000 Liters Liter (L)

Ph Level : 7 to 8

Turnkey Industrial CED Plant

Price 3500000 INR / Number

Minimum Order Quantity : 1 Number

Shelf Life : 1218 Months (for CED chemical)

Voltage : 380415 V, Three Phase

Tank Capacity : 1000 20000 Liters (customized)

Ph Level : 5.5 to 6.0

Conveyorised CED Plant

Price 8500000 INR / Number

Minimum Order Quantity : 1 Number

Shelf Life : 612 Months for CED bath (depends on maintenance)

Voltage : 380415 V, 3 Phase, 50 Hz

Tank Capacity : 500 L to 30000 L (customized)

Ph Level : 5.8 6.2

Industrial CED Plant

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Shelf Life : 12 Months

Voltage : 380V/415V, 3 Phase, 50 Hz

Tank Capacity : 500 Ltr 5000 Ltr

Ph Level : 5.5 6.5

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free