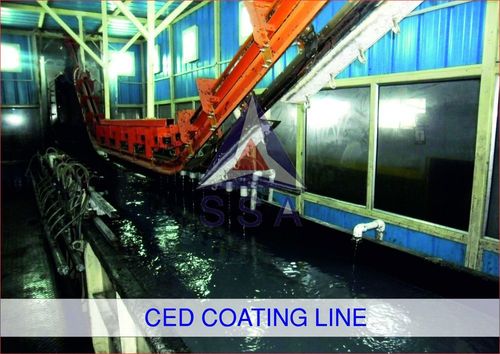

Turnkey Industrial CED Plant

Price 3500000 INR/ Number

Turnkey Industrial CED Plant Specification

- Equipment Type

- Automatic Industrial Plant

- Tank Capacity

- 1000 - 20000 Liters (customized)

- Packaging Type

- Standard Export Worthy Packaging

- Concentration

- 8-15% (Bath solution)

- Temperature Range

- 24C to 32C

- Ph Level

- 5.5 to 6.0

- Chemical Name

- Cathodic Electro Deposition (CED) Coat

- Grade Standard

- Industrial Grade

- Shelf Life

- 12-18 Months (for CED chemical)

- Equipment Type

- Turnkey Industrial CED Plant

- Product Type

- Turnkey CED Plant

- Dimension (L*W*H)

- Customized as per project requirements

- Voltage

- 380-415 V, Three Phase

- Installation and Commissioning

- Offered by Manufacturer

- Surface Pre-treatment

- Multi-stage (Degreasing, Phosphating, Rinsing, Activation)

- Efficiency

- Up to 95% transfer efficiency

- Control System

- PLC Based Automated Control

- Heating System

- Automatic Electric or Steam Heaters

- Power Consumption

- Depends on Plant Capacity (typically 5-25 kW/h)

- Pretreatment Line

- Integrated or Standalone as per requirement

- Service Support

- Available Nationwide

- Coating Thickness

- 15 to 25 Microns

- Application

- Automotive, Appliances, General Engineering

- Material of Construction

- Mild Steel with Anti-corrosive Lining / SS304 / SS316

About Turnkey Industrial CED Plant

Distinctive Features and Applications

The Turnkey Industrial CED Plant boasts an integrated or standalone pretreatment line, with advanced surface application including multi-stage degreasing, phosphating, rinsing, and activation. Its prodigious design ensures automatic electric or steam heating and accommodates coating surfaces for automotive, general engineering, and appliances. This system supports customized dimensions and delivers robust anti-corrosive coatings, enhancing durability. The packaging is export-worthy, reflecting exceptional safety and industrial-grade quality for diverse material protection needs.

Domestic Market Reach and Delivery Assurance

Our CED plant commands a strong market value within Indias main domestic markets. With secure shipping options and quick dispatch from the specified FOB port, clients benefit from timely deliveries. Lead times are tailored to project requirements, ensuring satisfaction and seamless installation. Standard export packaging further guarantees the pristine arrival of your equipment, reinforcing our commitment to quality and service. Choose us for reliability and responsive market support, wherever your facility operates in the nation.

FAQs of Turnkey Industrial CED Plant:

Q: How does the anti-corrosive lining benefit the CED plants performance?

A: The anti-corrosive lining, whether in mild steel or stainless steel options like SS304/SS316, extends the lifespan of the plant and safeguards the coating process against chemical degradation, ensuring consistent and reliable results.Q: What is the typical process involved in coating with the CED plant?

A: The process includes multi-stage surface pretreatmentdegreasing, phosphating, rinsing, and activationfollowed by application of the CED chemical in a controlled environment to achieve a uniform 15-25 micron film, supported by automated PLC controls.Q: Where can this Turnkey Industrial CED Plant be installed?

A: The plants adaptability in dimension allows installation across a variety of industries including automotive manufacturing, home appliance assembly, and general engineering facilities across India, with nationwide service support available.Q: When can I expect delivery after placing an order?

A: Delivery times are dependent on your projects specifications and customization needs, but quick dispatch is facilitated through secure shipping from our specified FOB port for timely installation.Q: What are the main features that make this plant a popular purchase?

A: Key features include prodigious coating efficiency (up to 95% transfer), customizable capacity, PLC-based automation, robust construction materials, multi-stage pre-treatment, and comprehensive after-sales service, making it a leading solution in industrial coating technology.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

Cathodic Electro Deposited Plant

Price 1750000 INR / Unit

Minimum Order Quantity : 1 Unit

Tank Capacity : 5000 L

Temperature Range : 22C 32C

Packaging Type : Custom (As per requirement)

Equipment Type : Electroplating Machine

Dunking Type CED Plant

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Tank Capacity : 100010000 Liters (customizable)

Temperature Range : 20C 30C

Packaging Type : Standard Export/Industrial Packaging

Equipment Type : Other, Dunking Type CED Plant

ED Plant

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Tank Capacity : 500 L 50000 L

Temperature Range : 10C 50C

Packaging Type : Standard packaging

Equipment Type : Other, ED Plant

Electrostatic Coating Gun

Price 12500 INR / Number

Minimum Order Quantity : 1 Number

Tank Capacity : 500 ml

Temperature Range : 10C to 45C

Packaging Type : Box

Equipment Type : Other, Electrostatic Coating Gun

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free