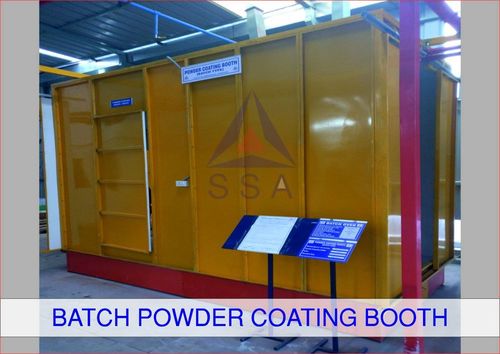

Batch Booth

Price 53000 INR/ Unit

Batch Booth Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Batch Processing

- Condition

- New

- Technology

- Powder Coating Technology

- Product Type

- Batch Booth

- Dimension (L*W*H)

- 2000 mm x 1500 mm x 2000 mm

- Power Mode

- Electric

- Voltage

- 415 V

- Power Consumption

- 7.5 kW

- Application

- Industrial powder coating

- Weight

- Approx. 400 kg

- Coating Type

- Powder Coating

- Filter Type

- Cartridge filters

- Finish

- Pre-coated

- Booth Type

- Modular

- Control System

- PLC Based

- Working Speed

- Variable

- Noise Level

- < 80 dB

- Air Flow

- Cross Draft

About Batch Booth

Product details

| Air-Flow Direction | Lateral Undershot Type,Cross-Flow Type,Fully Undershot Type |

| Heating Mode | Electric,Diesel, Gas (LPG / PNG) |

| Material to be painted | Steel,Iron,Aluminum |

Reliable Modular Design for Versatile Operations

Our Batch Booth offers flexibility thanks to its modular construction, making it easy to install, expand, or relocate as your operations grow. Made from mild steel with a pre-coated finish, it is engineered for strength and durability, ensuring constant support for a broad range of industrial powder coating tasks.

Advanced Control for Precision and Efficiency

Equipped with a PLC-based control system, this booth enables precise regulation of the coating process. Users can adjust working speed for different job requirements, allowing for efficient operation and consistent results, while maintaining energy consumption and streamlined workflow.

Clean Operation and Enhanced Workplace Safety

The cross draft airflow system, combined with advanced cartridge filters, maintains superior air quality inside the booth, capturing excess powders and reducing contamination risk. Noise levels remain below 80 dB, contributing to a safer and more comfortable working environment.

FAQ's of Batch Booth:

Q: How does the cross draft airflow enhance powder coating performance in the Batch Booth?

A: The cross draft airflow design ensures uniform air movement across the booth, which effectively directs overspray towards the cartridge filters. This results in improved powder collection, reduced contamination, and an overall consistent, high-quality coating finish.Q: What type of filters does the booth use and how are they maintained?

A: This booth utilizes high-efficiency cartridge filters that capture fine powder particles. These filters are easy to access and maintain, typically requiring periodic cleaning or replacement based on usage intensity, ensuring continued optimal performance.Q: When is batch processing with this booth most beneficial for industrial applications?

A: Batch processing is ideal when handling varied or smaller production runs, allowing you to quickly adapt to different coating requirements. This flexibility makes the booth well-suited for industries needing frequent changes or specialized coatings.Q: Where can this booth be installed and what space requirements are necessary?

A: With dimensions of 2000 mm x 1500 mm x 2000 mm and a modular design, the booth can be installed in a range of industrial settings, including production floors and dedicated coating areas. Adequate ventilation and electrical supply are recommended for optimal operation.Q: What is the process for operating the PLC-based control system?

A: The PLC-based system simplifies the operation by allowing users to preset and adjust working speeds, monitor booth functions, and control airflow and filtration. Training is straightforward, and the intuitive controls improve efficiency and accuracy during powder coating.Q: How does variable working speed benefit industrial powder coating?

A: Variable working speeds enable operators to customize the coating process for different substrates, part sizes, and finish requirements. This flexibility increases productivity, reduces waste, and ensures better adherence and surface quality.Q: What are the advantages of using mild steel with pre-coated finish in this batch booth?

A: Mild steel construction provides structural strength, while the pre-coated finish offers enhanced resistance to corrosion and wear. This ensures a longer service life, reduced maintenance, and sustained performance in demanding industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Nano Powder Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Technology : Suction Feed

Material : MS / Al

Voltage : 110 V / 220 V / 415 V Volt (v)

Application : Powder Coating Recovery in Industrial Settings

SS Powder Coating Booth

Price 350000 INR / Piece

Minimum Order Quantity : 1 Plant

Technology : Other, Electrostatic Powder Coating

Material : Stainless Steel (SS)

Voltage : 220415 V AC Volt (v)

Application : Industrial metal finishing, metal furniture, automobile parts, etc.

Batch Powder Coating Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Technology : Other, Electrostatic Powder Coating

Material : Mild Steel

Voltage : 110 V / 220 V / 415 V Volt (v)

Application : Industrial Surface Coating

Cyclone Type Powder Recovery Booth

Price 116000 INR / Unit

Minimum Order Quantity : 1 Unit

Technology : Other, Cyclone Separation

Material : Mild Steel

Voltage : 230 V / 415 V

Application : Powder Coating Recovery

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS