Blasting MACHINE

Price 110000 INR/ Piece

Blasting MACHINE Specification

- Tank Capacity

- 80 L

- Grade Standard

- Industrial

- Temperature Range

- Ambient

- Packaging Type

- Wooden box

- Equipment Type

- Blasting MACHINE

- Usage

- Industrial

- Equipment Type

- Blasting MACHINE

- Product Type

- Blasting

- Dimension (L*W*H)

- 850 mm x 500 mm x 1350 mm

- Voltage

- 230 V

- Blasting Media Compatibility

- Abrasive media (sand, grit, glass beads, etc.)

- Machine Weight

- 115 kg

- Hopper Material

- Mild Steel

- Air Requirement

- 7-8 kg/cm²

- Operation Mode

- Manual

- Nozzle Diameter

- 6 mm

- Surface Finish

- Powder Coated

Blasting MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Cash Against Delivery (CAD), Cash in Advance (CID)

- Delivery Time

- 3-4 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

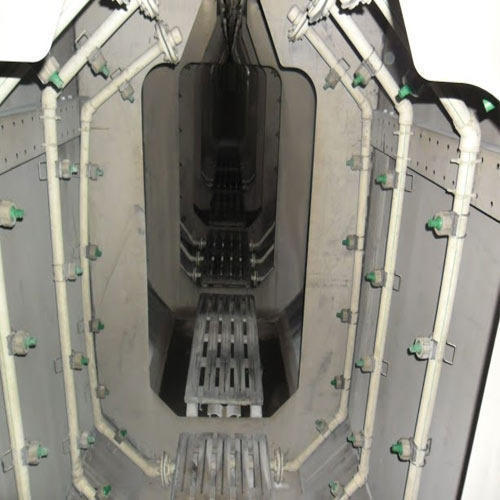

About Blasting MACHINE

We are leading manufacturer of Blasting

Shot blasting is the Cheapest and most effective method for Surface Preparation Shot Blasting provides a uniform and consistent fine matt or rough surface. The surface becomes perfectly suitable for painting, galvanizing and metal spraying

Shot blasting can form permanent bond between shot blasted surface and protective coating like paint, zinc and epoxy powder coating etc. It also reveals surface defects in the metal. It increases the life of protective coating adheres tenaciously to the scale-free, blast cleaned surface. Thus maintenance cost for repainting can be considerably reduced

Restrictive environmental legislation and a greater awareness of health hazards were the main reasons for development of Vacuum Blasting Machines. The advantages of the equipment are not limited to preventing environmental and health problems, in many applications it is also a fully justified method of surface preparation on an economic basis.

Disposal costs of hazardous waste is minimal by the use of recyclable abrasives, so the amount of abrasives used is much lower than compared with open-blasting. The equipment has many applications. Besides for construction and maintenance of ships, the equipment can also be used for the maintenance of bridges, machinery, power plants or for the renovation of concrete. Steel, shipbuilding , offshore and (petro) chemical industries and also for maintenance purpose in the civil works sector such as cleaning bridges , tunnels and buildings etc.

These are tailor-made or custom built machines designed for specific purposes wherein the work pieces may be tumbled, rotated, rolled, carried, and even pushed, all according to necessity, convenience and economy. In these machines the work is carried upon hangers suspended from an overhead monorail.

This type of machine may be classed as a single or multiple pass, indexing, spinner hanger or straight through type. Again the machine may be single or multi wheel type depending on the product size and the required output. The overhead conveyor type machine can be designed to carry weights up to 4 tons per hanger.

The layout of monorails circuits may be unlimited in variety. Overhead plants have two outstanding features; continuity of production and flexibility. There are very few work pieces that are not capable of being suspended by some type of suitable hanger. These help in Plate Cleaning Machine, Plate Blasting Machine,

Sheet Blasting Machine, and Vessel Cleaning Machine & Hanger Type Machine

Features:

- Remove rust, mill scale, heat scale and carbon build up from metals

- Strip paint, powder coating, plating and anodising from parts for rework

- Eliminate burrs, parting lines, flashing and other

- defects from castings and injection-molded parts

- Extract residual sand from castings

- Sand Removal

- Tube Cleaning

- Beautify steel, stainless steel, aluminium, brass and other metals with a matte finish

- Etch artwork and lettering into glass, stone, plastics, metal and other material

- Clean release agents and material buildup from molds

- Top quality

- Sturdy construction

- Flawless functionality

- Very durable

Specifications:

- Automatic Grade: Manual / Semi Auto / Automatic

- Capacity : 5 to 30 ton /day

- Machine Type: Portable Type

- Number of Doors: Single Door / Double Door

- Material: Stainless Steel / MS

- Power Source: Electric

- Installation: Pedestal

- Diameter: 400 and 500mm

- Wind Capacity: 5500 M3/H

Versatile Blasting for Industrial Surfaces

This blasting machine offers excellent compatibility with various abrasive media, including sand, grit, and glass beads, making it suitable for numerous industrial cleaning and surface preparation jobs. The 6 mm nozzle and sturdy construction consistently deliver effective results across multiple surfaces.

Durable Build and Efficient Design

Built using powder-coated mild steel, the machine stands up to tough industrial use. The sizable 80 L hopper allows extended operation, while the manual system gives the user precise control over the blasting process, making maintenance and operation straightforward.

FAQ's of Blasting MACHINE:

Q: How does the manual operation of the Blasting MACHINE work?

A: The machine is designed for manual handling, which allows the operator to directly control the blasting process using the handle and nozzle, ensuring targeted surface cleaning and preparation.Q: What types of abrasive media are compatible with this machine?

A: This Blasting MACHINE is compatible with various abrasive media, including sand, grit, glass beads, and similar materials, offering flexibility depending on your industrial application and required finish.Q: When is this machine most beneficial to use in industrial settings?

A: It is most beneficial for tasks that require high-quality surface cleaning or preparation, such as removing rust, old paint, or scale from metal surfaces before coating or welding, especially in workshops, factories, and maintenance departments.Q: Where can I use this Blasting MACHINE?

A: The machine is suitable for use in a wide range of industrial environments, including manufacturing plants, workshops, and service centers, anywhere heavy-duty surface treatment is required.Q: What is the process of setting up the machine for operation?

A: Setup involves positioning the machine at the worksite, filling the 80 L hopper with the chosen abrasive media, connecting to a compatible air compressor supplying 7-8 kg/cm2, and then operating the nozzle manually to direct the blast as needed.Q: What safety and operational benefits does the powder-coated mild steel construction provide?

A: The powder-coated mild steel construction enhances durability, resistance to corrosion, and ease of cleaning, contributing to operator safety and extending the machine's lifespan in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Treatment Line Category

Spray Cum Dip Plant

Price 2250000 INR / Plant

Minimum Order Quantity : 1 Plant

Tank Capacity : 400 Ltrs (standard) / Custom Liter (L)

Shelf Life : 12 Months Months

Ph Level : 6 9

Dimension (L*W*H) : Customizable as per requirement Millimeter (mm)

Spray Pre Treatment Pre Treatment Plants

Price 620000 INR / Plant

Minimum Order Quantity : 1 Plant

Tank Capacity : 5001000 Liter (L)

Shelf Life : 2 Years

Ph Level : 7 to 8

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Spray PT Plant

Price 440000 INR / Set

Minimum Order Quantity : 1 Set

Tank Capacity : 1000 Liters Liter (L)

Shelf Life : 2 Years

Ph Level : 7 to 8

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

spray washing

Price 350000 INR / Square Foot

Minimum Order Quantity : 1 Square Foot

Tank Capacity : 200 Liters

Shelf Life : 12 Months

Ph Level : 1113

Dimension (L*W*H) : 1200mm x 800mm x 1600mm

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS