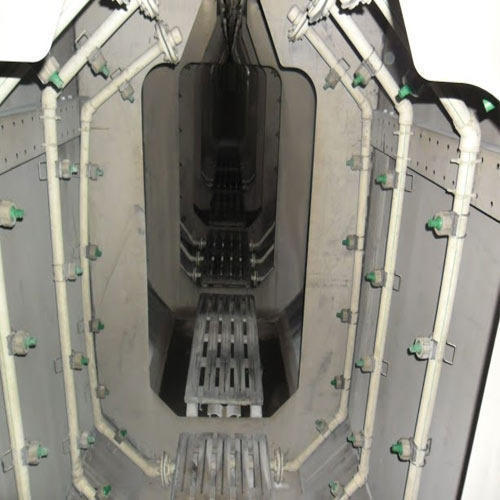

spray washing

Price 350000 INR/ Square Foot

spray washing Specification

- Grade Standard

- Industrial Grade

- Chemical Name

- Alkaline Detergent

- Tank Capacity

- 200 Liters

- Packaging Type

- Metal Cabinet

- Temperature Range

- 50C - 70C

- Ph Level

- 11-13

- Concentration

- 2-5% w/v

- Shelf Life

- 12 Months

- Usage

- Industrial

- Equipment Type

- Spray Washing Machine

- Product Type

- spray washing

- Dimension (L*W*H)

- 1200mm x 800mm x 1600mm

- Voltage

- 220-240V

- Compatible Substrate

- Metal, Plastic, Ceramic

- Safety Features

- Overload Protection, Emergency Stop Button

- Water Consumption

- 10-20 L/cycle

- Pump Power

- 1.5 HP

- Automation Grade

- Semi-automatic

- Mounting Type

- Floor Standing

- Nozzle Type

- Rotating Spray Nozzles

- Cleaning Efficiency

- 98%

- Material of Construction

- Stainless Steel 304

- Washing Cycle Time

- 2-10 Minutes

- Control Panel

- Digital PLC

About spray washing

Versatile Applications Across Industries

Our industrial spray washing machine excels in diverse settings including manufacturing plants, automotive facilities, and ceramic workshops. Used by engineers, technicians, and quality controllers, it efficiently powers through contaminants with alkaline detergent for large-scale batch cleaning. Its semi-automatic programmable operation ensures both flexibility and reliability for heavy-duty industrial use, supporting both regular and intensive cleaning routines.

Reliable Supply Ability & Transparent Policy

We assure high supply ability with prompt shipment from leading Indian FOB ports, maintaining competitive valuation and superior delivery rate. Sample policies are customer-friendly, offering easy access for initial evaluation. Each unit is expertly packaged in a robust metal cabinet to ensure pristine condition upon arrival, matching international standards for exporters and suppliers.

FAQ's of spray washing:

Q: How does the spray washing machine achieve a 98% cleaning efficiency?

A: The machine uses rotating spray nozzles and a high-performance 1.5 HP pump, combined with carefully controlled washing cycles and concentrated alkaline detergents, optimizing coverage and penetration for thorough contaminant removal.Q: What substrates can be cleaned with this spray washing equipment?

A: It is compatible with metal, plastic, and ceramic substrates, making it suitable for various manufacturing, processing, and quality assurance applications.Q: When should the alkaline detergent be replaced or replenished?

A: Alkaline detergent should be monitored regularly; ideally, replace or replenish when concentration drops below 2% w/v or after significant use cycles to maintain optimum pH (11-13) and cleaning performance.Q: Where is the spray washing machine manufactured and supplied from?

A: The equipment is manufactured, exported, and supplied from India by a reputable supplier with extensive experience in industrial cleaning systems.Q: What safety features are integrated into the spray washing machine?

A: Safety mechanisms include overload protection and an emergency stop button, ensuring operator security and preventing equipment damage during operation.Q: How is the washing process controlled and monitored?

A: The semi-automatic machine features a digital PLC control panel, enabling precise management of washing cycles, temperature, and detergent concentration for reliable, repeatable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Treatment Line Category

Spray PT Plant

Price 440000 INR / Set

Minimum Order Quantity : 1 Set

Tank Capacity : 1000 Liters Liter (L)

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Usage : Industrial

Equipment Type : Electroplating Machine

Spray Cum Dip Plant

Price 2250000 INR / Plant

Minimum Order Quantity : 1 Plant

Tank Capacity : 400 Ltrs (standard) / Custom Liter (L)

Dimension (L*W*H) : Customizable as per requirement Millimeter (mm)

Spray Pre Treatment Pre Treatment Plants

Price 620000 INR / Plant

Minimum Order Quantity : 1 Plant

Tank Capacity : 5001000 Liter (L)

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Usage : Industrial

Equipment Type : Electroplating Machine

Blasting MACHINE

Price 110000 INR / Piece

Minimum Order Quantity : 1 Piece

Tank Capacity : 80 L

Dimension (L*W*H) : 850 mm x 500 mm x 1350 mm

Usage : Industrial

Equipment Type : Other, Blasting MACHINE

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free