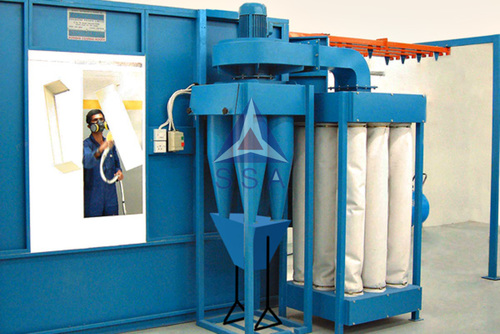

Conveyorised Powder Coating Booth

Price 350000 INR/ Unit

Conveyorised Powder Coating Booth Specification

- Usage

- Industrial

- Material

- Stainless Steel / Mild Steel

- Condition

- New

- Product Type

- Conveyorised Powder Coating Booth

- Technology

- Conveyorised Automatic System

- Dimension (L*W*H)

- Customized as per requirement Millimeter (mm)

- Power Mode

- Electric

- Voltage

- 380-440 V Volt (v)

- Power Consumption

- 7-15 kW (varies by model and size) Kilowatt (kW)

- Application

- Industrial, Powder Coating of Metal Parts

- Weight

- Depends on size and customization (typically 800-2000 kg) Kilograms (kg)

- Coating Type

- Powder

- Booth Type

- Open Face or Enclosed Type, Modular Design

- Number of Spray Guns

- Customizable (typically 2 to 8 guns)

- Booth Wall Finishing

- Anti-static Epoxy Coated

- Control Panel

- PLC Microprocessor Based Control

- Conveyor Type

- Overhead Mono-rail/ Power & Free/ I-beam

- Filter System

- Multi-stage Cartridge/Bag Filters with Pulse-Jet Cleaning

- Air Flow Type

- Down Draft / Side Draft

- Temperature Control

- Digital Thermostatic, Up to 250°C (if with curing oven integration)

- Recovery System

- Automatic Powder Recovery and Recycle

- Noise Level

- <75 dB(A)

About Conveyorised Powder Coating Booth

Key Features & Industrial Applications

The Conveyorised Powder Coating Booth is used for precise, high-volume powder coating applications in industrial environments. Notable features include advanced PLC controls, efficient powder recovery, digital temperature management, and robust modular construction. Used for coating various metal parts, this system can be customized with multiple spray guns and conveyor types. Ideal for manufacturers seeking reliable, high-speed performance, it offers versatility and durability in production lines.

Delivery, Domestic Reach & Supply Capability

Delivery time for the Conveyorised Powder Coating Booth depends on proposal amount and customization needs, typically ranging from a few weeks. Shipped across India to meet industrial demands, the system is offered at the lowest price for quality and value. Our main domestic market includes all manufacturing hubs, with a supply ability designed to handle both bulk and specialty orders, ensuring efficient fulfillment for every client.

FAQ's of Conveyorised Powder Coating Booth:

Q: How is the Conveyorised Powder Coating Booth delivered and installed?

A: Once the proposal amount is finalized, the booth is shipped directly to client locations across India. Our team provides installation support, ensuring proper assembly and integration with existing lines.Q: What types of spray guns can be customized in the booth?

A: The system allows customization of the number of spray guns, typically ranging from two to eight. This flexibility helps match the coating process to specific production needs.Q: What is the process for powder recovery and recycling in this booth?

A: Automatic powder recovery is managed through a multi-stage cartridge or bag filter system with pulse-jet cleaning. Collected powder is recycled to minimize waste and operational costs.Q: Where can this booth be used?

A: This booth is designed for industrial applications, especially for powder coating metal parts. It is suitable for manufacturers, exporters, service providers, and suppliers in various sectors.Q: What are the benefits of the PLC microprocessor-based control panel?

A: PLC microprocessor-based control ensures precise operation, improved automation, easy monitoring, and enhanced efficiency in powder coating processes.Q: When should I consider the enclosed type versus open face booth design?

A: Choose enclosed booths for higher containment and cleaner environments, while open face designs suit spaces where easy operator access and flexibility are prioritized.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

Powder Coating Booth with Mono Cyclone

Price 250000 INR / Piece

Minimum Order Quantity : 1 Plant

Processing Type : Standard

Voltage : 110 V / 220 V / 415 V Volt (v)

Material : MS / AL

Application : Powder Coating Recovery in Industrial Settings

Plastic Powder Coating Booth

Price 611000 INR / Unit

Minimum Order Quantity : 1 Unit

Processing Type : Customized

Voltage : 220440 Volt (v)

Material : Mild Steel

Application : Powder Coating Recovery in Industrial Settings

Batch Booth

Price 53000 INR / Unit

Minimum Order Quantity : 1 Unit

Processing Type : Other, Batch Processing

Voltage : 415 V

Material : Mild Steel

Application : Industrial powder coating

Multi Cyclone Powder Booth

Price 206000 INR / Unit

Minimum Order Quantity : 1 Unit

Processing Type : Other, Powder Coating

Voltage : 415 V

Material : Mild Steel

Application : Industrial Powder Coating

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free