Cyclone Powder Booth

Price 116000 INR/ Unit

Cyclone Powder Booth Specification

- Usage

- Industrial

- Material

- Powder Coated Steel

- Processing Type

- Powder Coating

- Condition

- New

- Technology

- Cyclone Separation

- Product Type

- Cyclone Powder Booth

- Dimension (L*W*H)

- Custom/As per requirement

- Power Mode

- Electric

- Voltage

- 220-415 V

- Power Consumption

- Low to Medium (varies by size/model)

- Application

- Industrial Powder Coating Operations

- Weight

- Depends on Model (Typically 250-500 kg)

- Coating Type

- Powder

- Door Type

- Front & Side Access Doors

- Booth Lighting

- Integrated LED Lighting

- Color

- White/Grey (Standard) or Customizable

- Air Flow Rate

- 3000-7000 m³/hr (varies by model)

- Control System

- PLC Based (Optional)

- Installation

- Professional Installation Recommended

- Dust Collection Efficiency

- Up to 98%

- Noise Level

- Below 80 dB

- Filter Type

- High Efficiency Cartridge/Polyester

- Mobility

- Fixed or Movable (Depending on model)

About Cyclone Powder Booth

Product details

| Booth Size (mm X mm X mm) | 2000 / 2500 / 3000 mm / ...... |

| Air-Flow Direction | Fully Undershot Type,Cross-Flow Type |

| Heating Mode | Diesel,Electric, Gas |

| Material to be painted | Iron,Steel,Aluminum |

Advanced Cyclone Separation Technology

Equipped with innovative cyclone separation, the booth ensures up to 98% dust collection efficiency-minimizing airborne particulates and ensuring a cleaner workspace. Its filtration system, utilizing high-efficiency cartridge or polyester filters, further enhances air purity, making it ideal for rigorous industrial powder coating operations.

Flexible Design and Customization

The Cyclone Powder Booth offers flexibility in installation and operation, with both fixed and movable options to suit various workspace requirements. You can customize color, dimensions, and access doors for seamless integration into your production line. The robust powder-coated steel build guarantees long-lasting performance.

Integrated Lighting and Controls for Enhanced Usability

Integrated LED lighting provides bright, uniform illumination, improving operator accuracy and safety. Optional PLC-based control systems deliver automated, precise operation tailored to your workflow needs, streamlining the powder coating process and boosting overall efficiency.

FAQ's of Cyclone Powder Booth:

Q: How does the Cyclone Powder Booth achieve high dust collection efficiency?

A: The booth employs advanced cyclone separation technology, which efficiently removes powder particles from the air stream. Combined with high-efficiency cartridge or polyester filters, this system achieves up to 98% dust collection efficiency, ensuring a cleaner and safer working environment.Q: What are the benefits of integrated LED lighting in the powder booth?

A: Integrated LED lighting provides consistent and bright illumination across the booth. This enhances visibility for operators, allowing for more accurate powder application and improved safety during industrial processes.Q: When is professional installation recommended for this booth?

A: Professional installation is recommended at the time of setup to ensure optimal placement, electrical connections, and performance. Expert installers will properly assemble the booth, calibrate the airflow, and verify that all features are operating at their best.Q: Where can the Cyclone Powder Booth be used?

A: This booth is designed for industrial powder coating operations and is suitable for use in manufacturing plants, automotive workshops, and other environments where high-efficiency dust collection and controlled coating processes are essential.Q: What is the process for customizing the booth's size and color?

A: Customization is available during the ordering process. Clients can specify preferred dimensions and colors-choosing from standard white/grey or custom options-to ensure the booth fits seamlessly into their production area and matches corporate branding.Q: How does the booth ensure quiet operation during use?

A: The Cyclone Powder Booth's design, along with its advanced filtration system, keeps noise levels below 80 dB. This makes for a quieter working environment, reducing operator fatigue and improving overall workplace comfort.Q: What are the main usage benefits of the Cyclone Powder Booth?

A: Benefits include high dust collection efficiency for air quality, flexible mobility and customization, robust powder-coated steel construction, integrated lighting for improved workflow, and optional PLC controls to enhance process automation and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Coating Booth Category

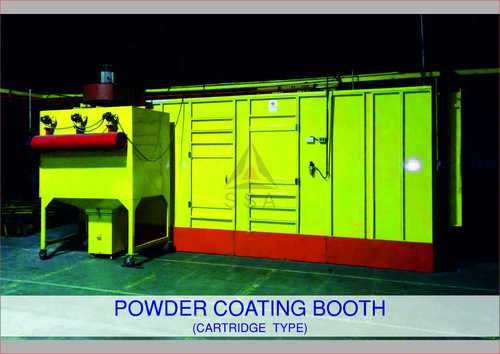

Powder Coating Booth with Cartridge Filter

Price 323000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Condition : New

Power Mode : Electric

Processing Type : Customized

Coating Booth

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380V

Condition : New

Power Mode : Electric

Processing Type : Other, Automatic

Conveyorised Powder Booth

Price 170000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380440 V

Condition : New

Power Mode : Electric

Processing Type : Other, Powder Coating

Cartridge Type Powder Recovery Booth

Price 440000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Condition : New

Power Mode : Electric

Processing Type : Other, Powder Recovery

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free