Spray Phosphating Systemd

Price 3500000 INR/ Plant

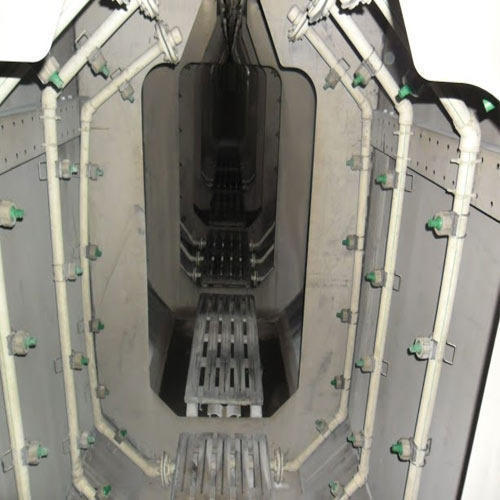

Spray Phosphating Systemd Specification

- Tank Capacity

- 500 to 6000 (customizable) Liter (L)

- Temperature Range

- 50C - 70C Celsius (oC)

- Chemical Name

- Zinc Phosphating Solution

- Concentration

- 5-10% w/v (as per process requirement)

- Shelf Life

- 12 Months

- Equipment Type

- Fully Automatic/Semi-Automatic

- Packaging Type

- Standard export-quality packaging

- Ph Level

- 2.5 - 3.5

- Grade Standard

- Industrial Grade

- Usage

- Industrial

- Size

- 4800 x 2500 x 900 mm

- Equipment Type

- Electroplating Machine

- Dimension (L*W*H)

- 4000 x 3000 x 2500 mm Millimeter (mm)

- Surface Finishing

- Uniform, matte, grey-black

- Number of Stages

- 3 to 7 Stage (customized)

- Installation

- On-site installation and commissioning included

- Material of Construction

- Mild Steel with corrosion-resistant lining/SS304 as option

- Service Support

- Available Pan India

- Flow Rate

- 60 to 500 LPH (customizable)

- Application

- Automobile, General Engineering, Appliances

- Heating Source

- Electrical/Steam Heater

- Control Panel

- PLC-based with safety interlocks

- Mobility

- Fixed or Skid-mounted

- Spray Nozzle Type

- High pressure, fan type

About Spray Phosphating Systemd

Customizable Multistage Phosphating System

Superior Surface Finishing and Protection

Comprehensive Service and On-Site Installation

FAQs of Spray Phosphating Systemd:

Q: How does the spray phosphating process work in this system?

Q: What are the benefits of using this spray phosphating system for my application?

Q: When should I consider customizing the number of process stages or tank capacity?

Q: Where is the spray phosphating system installed and commissioned?

Q: What materials of construction are available for the system?

Q: How is the equipment controlled and what safety features are included?

Q: What is the shelf life and recommended concentration of the zinc phosphating solution?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Treatment Line Category

Spray PT Plant

Price 440000 INR / Set

Minimum Order Quantity : 1 Set

Voltage : 220440 Volt (v)

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Tank Capacity : 1000 Liters Liter (L)

Equipment Type : Electroplating Machine

Spray Cum Dip Plant

Price 2250000 INR / Plant

Minimum Order Quantity : 1 Plant

Voltage : 415V AC Volt (v)

Dimension (L*W*H) : Customizable as per requirement Millimeter (mm)

Tank Capacity : 400 Ltrs (standard) / Custom Liter (L)

Pre-Treatment Plants

Price 1800000 INR / Plant

Minimum Order Quantity : 1 Plant

Voltage : 220440 Volt (v)

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Tank Capacity : 5001000 Liter (L)

Equipment Type : Electroplating Machine

spray washing

Price 350000 INR / Square Foot

Minimum Order Quantity : 1 Square Foot

Voltage : 220240V

Dimension (L*W*H) : 1200mm x 800mm x 1600mm

Tank Capacity : 200 Liters

Equipment Type : Other, Spray Washing Machine

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free