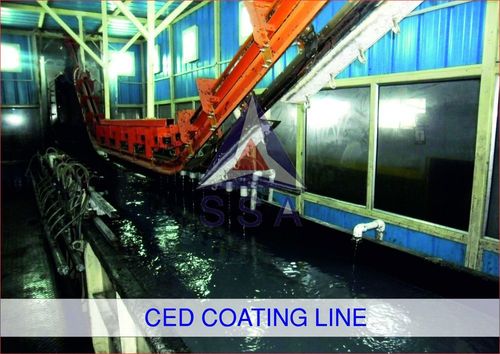

CED Plant

Price 5500000 INR/ Plant

CED Plant Specification

- Shelf Life

- Months

- Concentration

- 12-16% (Epoxy) in Bath

- Tank Capacity

- 1000 Liters Liter (L)

- Grade Standard

- Industrial Grade

- Packaging Type

- Assembled/Modular Packaging

- Temperature Range

- 28 32C Celsius (oC)

- Ph Level

- 5.8 - 6.2

- Chemical Name

- Cathodic Epoxy

- Usage

- Industrial

- Size

- 4800 x 2500 x 900 mm

- Equipment Type

- Electroplating Machine

- Dimension (L*W*H)

- 4000 x 3000 x 2500 mm Millimeter (mm)

- Voltage

- 380 V Volt (v)

- Automation Grade

- Semi-Automatic/Automatic

- Agitator

- Included

- Filtration System

- Multi-stage Cartridge Filter

- Control Panel

- Digital/PLC Based

- Color

- Customized

- Surface Finish

- Corrosion Resistance

- Production Capacity

- Custom (from 5 to 50 units/hr)

- Circulation Pump

- Centrifugal, 1.5 HP

- Installation Service

- Available

- Insulation

- Thermal Insulation Provided

- Application

- Automotive, Sheet Metal, Industrial Components

- Coating Thickness

- 10-25 Micron

- Material

- Mild Steel (MS) with Epoxy Paint

- Power Consumption

- 20-35 KW

About CED Plant

Our well known company provides one of the best water based coatings method done on metal components. It is done by our experienced professionals keeping the component connected to a circuit. Furthermore, this is gettable at most economical prices. And in order to match the convenience of the valued clients, we provide this coating forCED Plantg n time bound manner. In addition to this, CED coating is extensively used for below provided reasons.

- Covers a wide range of materials (aluminum and steel castings, forgings and sheet metal components)

- Relatively high speed coating

- Aqueous process, hence free of fire risk

- Uniform coating thickness without porosity

- Parts of complex shapes and cavities can be fully covered

- Efficient utilization of coating materials

- Environmental friendly

- Superiorchemical resistance

- Mechanical durability

- High Salt Spray life

- Good corrosion resistance

It is water based coating method done on metal components. Coating is done by keeping the component connected to a circuit as the cathode and positively charged paint particles (anode) suspended in aqueous medium are deposited under direct current. Deposited film does not re-dissolve and the un-deposited material is rinsed off.

CED coating is preferred because of its:

- Uniform coating thickness without porosity

- Parts of complex shapes and cavities can be fully covered

- Efficient utilization of coating materials

- Covers a wide range of materials (aluminum and steel castings, forgings and sheet metal components)

- Relatively high speed coating

- Aqueous process, hence free of fire risk

- Environmental friendly

- Superior chemical resistance

- Mechanical durability

- High Salt Spray life

- Good corrosion resistance

- Dunking type

- Conveyorised type

Advanced Filtration and Control

The CED Plant is engineered with a multi-stage cartridge filtration system and digital/PLC-based control panel. This ensures accurate management of chemical concentrations and effective removal of particulates, providing a reliable, consistent finish. The integrated centrifugal pump and agitator facilitate uniform coating application and enhance operational efficiency.

Corrosion-Resistant Epoxy Coating

Utilizing cathodic epoxy with a bath concentration of 12 to 16%, the plant achieves a highly effective corrosion-resistant surface. Coating thicknesses between 10 to 25 microns preserve component integrity, making it ideal for automotive or industrial applications exposed to challenging environments.

FAQs of CED Plant:

Q: How does the CED Plant provide corrosion-resistant finishes?

A: The plant utilizes a cathodic epoxy coating process, applying an epoxy layer with a thickness of 10 to 25 microns. This results in a highly corrosion-resistant surface that protects automotive, sheet metal, and industrial components against oxidation and environmental wear.Q: What is the typical usage process for this CED Plant?

A: Operators load components into the system, which then carries out cleaning and coating through semi-automatic or fully automatic cycles. The centrifugal pump and agitator maintain chemical dispersion, while the multi-stage filter ensures purity. The digital/PLC panel allows precise control of all process parameters.Q: When is installation service available for the CED Plant?

A: Installation services are available upon purchase at client sites across India. Qualified engineers oversee the modular or assembled installation, ensuring seamless integration with existing infrastructure.Q: Where can the CED Plant be used effectively?

A: The plant is suitable for applications in automotive parts manufacturing, sheet metal processing, and a wide variety of industrial component production environments, thanks to its flexible automation options and corrosion-resistant features.Q: What are the main benefits of using this CED Plant?

A: Users benefit from customizable production capacity, high-quality corrosion resistance, automated process control, thermal insulation, and professional installation. This ensures durability, process reliability, and tailored solutions to specific manufacturing requirements.Q: How is the filtration process managed in the system?

A: A multi-stage cartridge filtration system continuously purifies the bath solution, removing particles and contaminants to maintain optimal coating performance and extend chemical shelf life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

CED Coating Plant

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V AC, 3 Phase, 50 Hz

Concentration : 815% Solids

Tank Capacity : 1000 to 15000 Litres (customized)

Grade Standard : Industrial Grade

Dunking Type CED Plant

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380415V, 3 Phase, 50 Hz

Concentration : As per process requirement

Tank Capacity : 100010000 Liters (customizable)

Grade Standard : Industrial Grade

Turnkey Industrial CED Plant

Price 3500000 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 380415 V, Three Phase

Concentration : 815% (Bath solution)

Tank Capacity : 1000 20000 Liters (customized)

Grade Standard : Industrial Grade

Electrostatic Coating Gun

Price 12500 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 220V AC

Concentration : Standard Application Mix

Tank Capacity : 500 ml

Grade Standard : Industrial Grade

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS