Mini CED Plant

Price 1800000 INR/ Number

Mini CED Plant Specification

- Packaging Type

- Standard Export Packaging

- Concentration

- 5% - 15% (as per application)

- Chemical Name

- Cathodic Electro Deposition (CED) Paint

- Temperature Range

- 22C - 35C

- Ph Level

- 5.5 to 6.2

- Grade Standard

- Industrial Grade

- Shelf Life

- 12 Months

- Tank Capacity

- 250-1000 Liters (customizable)

- Usage

- Industrial

- Equipment Type

- Coating & Painting Plant

- Product Type

- Mini CED Plant

- Dimension (L*W*H)

- As per design (Typically Compact Size)

- Voltage

- 220-380 V

- Automation Grade

- Semi-Automatic/Automatic

- Surface Finish

- Powder Coated/ Painted

- Coating Efficiency

- Up to 90%

- Installation Service

- Available

- Control Panel

- PLC based digital control

- Number of Tanks

- 3 to 6 (as required)

- Material of Construction

- Mild Steel with Anti-Corrosive Coating

- Power Source

- Electric

- Filtration System

- Included

About Mini CED Plant

Product details

| Air-Flow Direction | Cross-Flow Type, Fully Undershot Type, Lateral Undershot Type |

| Automation Grade | Automatic, Semi-Automatic |

| Heating Mode | Diesel, Electric, Infrared Ray, Gas |

| Material to be Coated | Steel, Aluminium, Iron |

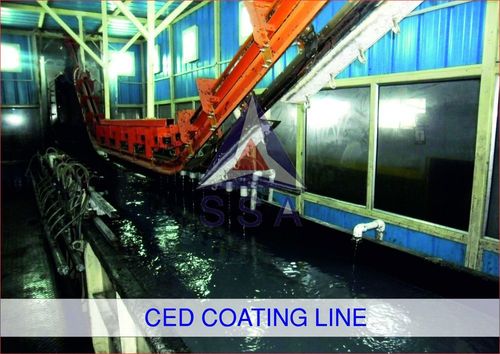

Advanced Coating Technology for Industry

The Mini CED Plant utilizes Cathodic Electro Deposition (CED) to provide superior corrosion resistance and a fine, even coating finish. Its compact, customizable build ensures seamless integration into existing manufacturing layouts, making it an ideal solution for industries aiming to improve surface durability and product quality.

Integrated Automation and Control

This plant's PLC-based digital control panel allows precise process management, minimizing manual intervention. Available in both semi-automatic and automatic models, the system enhances productivity while ensuring safety and consistency in operations. Its digital controls also streamline monitoring and troubleshooting.

Customized for Your Application

With tank capacities ranging from 250 to 1000 liters and the option for powder-coated or painted surface finishes, the Mini CED Plant adapts to specific industrial needs. Adjustable concentrations (5%-15%), pH levels, and temperature ranges ensure optimal coating results for diverse manufacturing applications.

FAQ's of Mini CED Plant:

Q: How does the Mini CED Plant improve coating efficiency?

A: The Mini CED Plant achieves up to 90% coating efficiency by leveraging Cathodic Electro Deposition technology, ensuring a uniform and robust paint layer. Its advanced filtration system and precise process control minimize defects and enhance coverage on various metal parts.Q: What is the process involved in operating this plant?

A: Operation involves loading cleaned components into the plant's tanks, where automated or semi-automatic systems manage the sequence of pre-treatment, CED coating, and rinsing. The PLC-based control panel streamlines each stage, ensuring consistent results and efficient chemical usage.Q: When should the chemical solution be replaced or maintained?

A: Chemical solutions should be monitored regularly, with replacement or replenishment based on concentration, pH (5.5-6.2), and visual inspection. Typical shelf life is 12 months, but usage patterns and production volume can affect maintenance schedules.Q: Where can the Mini CED Plant be installed?

A: The compact design allows installation within established industrial facilities across various manufacturing sectors. Installation service is provided to ensure proper setup and seamless integration into your existing workflows.Q: What are the main benefits for industrial users?

A: Industrial users gain improved corrosion resistance, a long-lasting finish, enhanced productivity through automation, and reduced operating costs thanks to efficient chemical use and minimized rework. The plant's flexibility makes it suitable for a broad range of component sizes and types.Q: How is power managed in the Mini CED Plant?

A: The plant operates on standard industrial electric supply (220-380V), with digital PLC controls managing energy consumption efficiently. Power requirements are adaptable based on the automation grade and plant capacity selected.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

CED Coating Plant

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Concentration : 815% Solids

Packaging Type : Modular Skid / Containerized

Chemical Name : EpoxyPolyester Resin Blend

Voltage : 415 V AC, 3 Phase, 50 Hz

Turnkey Industrial CED Plant

Price 3500000 INR / Number

Minimum Order Quantity : 1 Number

Concentration : 815% (Bath solution)

Packaging Type : Standard Export Worthy Packaging

Chemical Name : Cathodic Electro Deposition (CED) Coat

Voltage : 380415 V, Three Phase

CED Plant

Price 5500000 INR / Plant

Minimum Order Quantity : 1 Plant

Concentration : 1216% (Epoxy) in Bath

Packaging Type : Assembled/Modular Packaging

Chemical Name : Cathodic Epoxy

Voltage : 380 V Volt (v)

ED Coating Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Concentration : Varies as per process

Packaging Type : As per client requirement

Chemical Name : Electrophoretic Paint

Voltage : 380V / 415V Volt (v)

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS